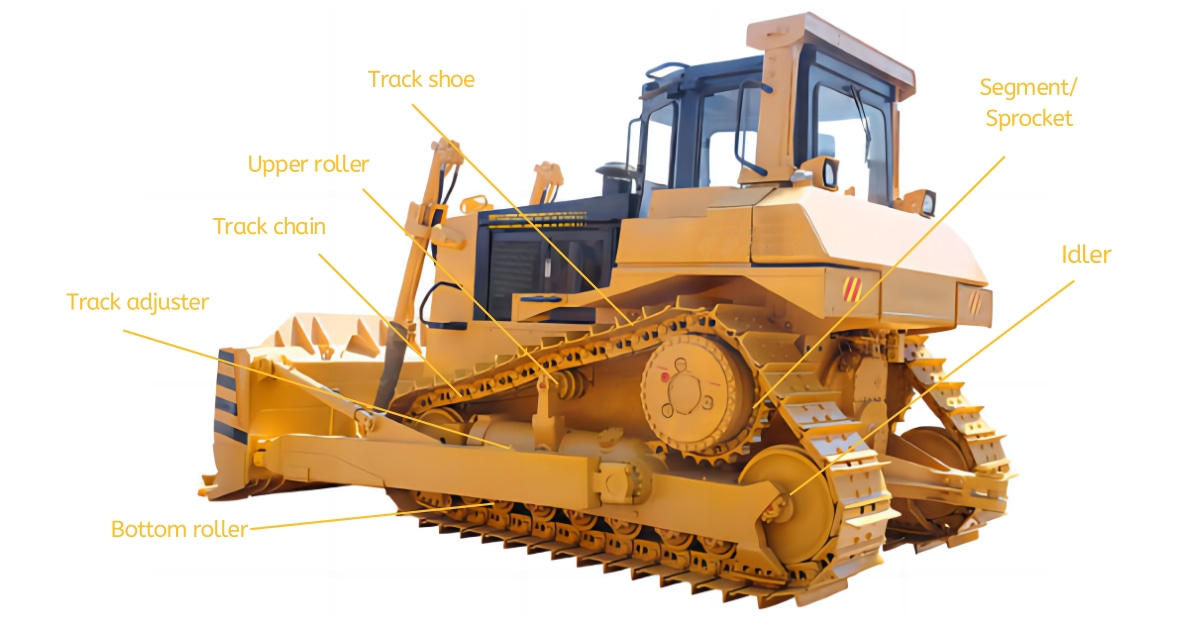

Dozer Undercarriage Parts

Introducing the D9G Dozer Carrier Roller CR1728 3P3403, perfectly designed to fit the impeccable machinery of Caterpillar. Crafted with utmost precision and exceptional quality, this roller guarantees an unrivaled performance in the field of heavy-duty equipment.

| Part Name | D9G Dozer Carrier Roller CR1728 3P3403 Fit For Caterpillar |

| Material | 40SiMnTi/50Mn/35MnB/40MnB/40Mn2 |

| Finish | Smooth |

| Processing | Forging, Casting, Machining, Heat treatment |

| Surface Hardness | HRC48-54,deepth:4mm-10mm |

| Delivery Time | Within 15days after payments. |

| MOQ | 2set |

D9G Dozer Carrier Roller CR1728 3P3403 Fit For Caterpillar, also compatible the machine as below: caterpillar 594 62H-1-82 D9H 90V-1-UP D9H 97V-1-UP D9H 98V-1-UP, Liebherr R981HD R982HD 1° TYPE R982HD 2° TYPE R984B LITRONIC.

In the undercarriage system of a bulldozer, the dozer track roller and dozer carrier roller each perform different functions, and while they have some similarities, they also have distinct roles.

Similarities:

Weight Support: Both components are used to support the weight of the bulldozer, ensuring that the equipment can operate smoothly on various terrains.

Providing Stability: They work together to maintain the stability and mobility of the bulldozer, which is crucial for the overall performance of the equipment.

Differences:

Position and Role:

The track rollers are typically located at the bottom of the track and are primarily responsible for bearing most of the weight of the bulldozer. They assist in reducing ground friction through their rolling action, helping the bulldozer move across different terrains.

On the other hand, the carrier rollers are located at the top or middle position of the track. They are mainly used to guide the track chain and provide support and guidance for the upper part of the track chain. Carrier rollers help prevent the track chain from derailing and ensure its normal operation.

In summary, although both the track rollers and carrier rollers are critical components of the bulldozer's undercarriage system, they have significant differences in terms of position, function, and design. The track rollers focus more on supporting weight and reducing friction, while the carrier rollers are geared towards guiding the track chain and providing the necessary support.

The high-quality dozer carrier rollers we produce have two notable features:

Durability and Wear Resistance: High-quality carrier rollers are typically made from premium materials, such as 40Mn2 steel, and undergo advanced processes like medium-frequency quenching, carbon dioxide gas shielded welding, and tempering. These processes ensure their durability and wear resistance in harsh working environments.

Internal Lubrication Design: The design and manufacturing of the carrier rollers fully consider internal lubrication, which helps reduce friction and extend their service life.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported