Dozer Undercarriage Parts

D8H Bulldozer Lower Roller Single Flange CR2796 6P4897 7S9041 Fit For Caterpillar

The extraordinary D8H Bulldozer Lower Roller Single Flange CR2796 6P4897 7S9041 Fit For Caterpillar, This indispensible component guarantees optimal performance, unfaltering reliability, and unmatched durability.

D8H Bulldozer Lower Roller Single Flange CR2796 6P4897 7S9041 Fit For Caterpillar also compatible with machine below: Caterpillar crawler loader 583H, dozer D8H, D8K.

D8H Bulldozer lower roller single flange part number: BERCO CR2796, CR2798, CR4562, CATERPILLAR 6P4897, 7S9041, 9P3308, ITM A0108000M00, LIEBHERR 5800163.

How to Properly Inspect and Maintain Bulldozer Lower Rollers and Their Related Components

Proper inspection and maintenance of bulldozer lower rollers and their related components require following these steps:

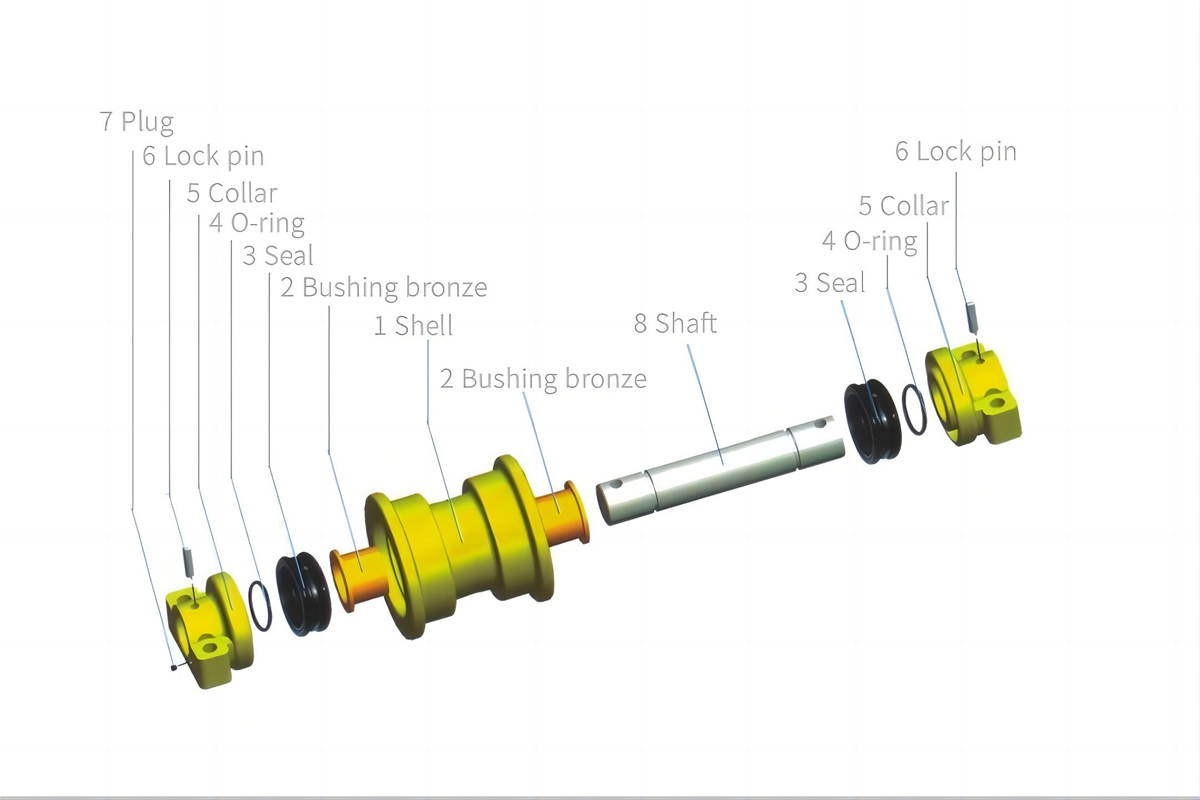

Visual Inspection of Appearance and Material: First, check the appearance of the lower roller for any obvious damage, deformation, or cracks to ensure that its appearance and structure are intact.

Wear Detection: The lower roller experiences friction with the track structure during use, leading to wear. Therefore, it is necessary to regularly check the wear amount of the lower roller.

Check Bolt Tightness: During routine maintenance, check the installation bolts of the bulldozer lower roller and carrier roller, the sprocket tooth block installation bolts, the track shoe installation bolts, the lower roller guard plate installation bolts, and the diagonal brace head installation bolts to ensure they are properly tightened.

Air Tightness Test: Conduct an air tightness test on the bulldozer lower roller to ensure its sealing performance is good.

Axle Inspection: Inspect the axle of the bulldozer lower roller for any abnormal wear or damage.

Eliminate Track Gouging Issues: If track gouging is detected (i.e., the lower roller is misaligned with the symmetrical center plane), use a string method to check and adjust the position of the lower roller.

Preparation Before Disassembly: Before disassembling, familiarize yourself with the relevant manuals and technical documents, and follow the specified procedures. Before disassembly, drain the oil from each component and observe the color, viscosity, impurities, and any other abnormalities in the oil to assess the wear and condition of the components.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported