Dozer Undercarriage Parts

The D7G bulldozer is typically equipped with 6 single flange track rollers and 6 double flange track rollers. Before purchasing, please ensure your machine model and contact us for more product information.

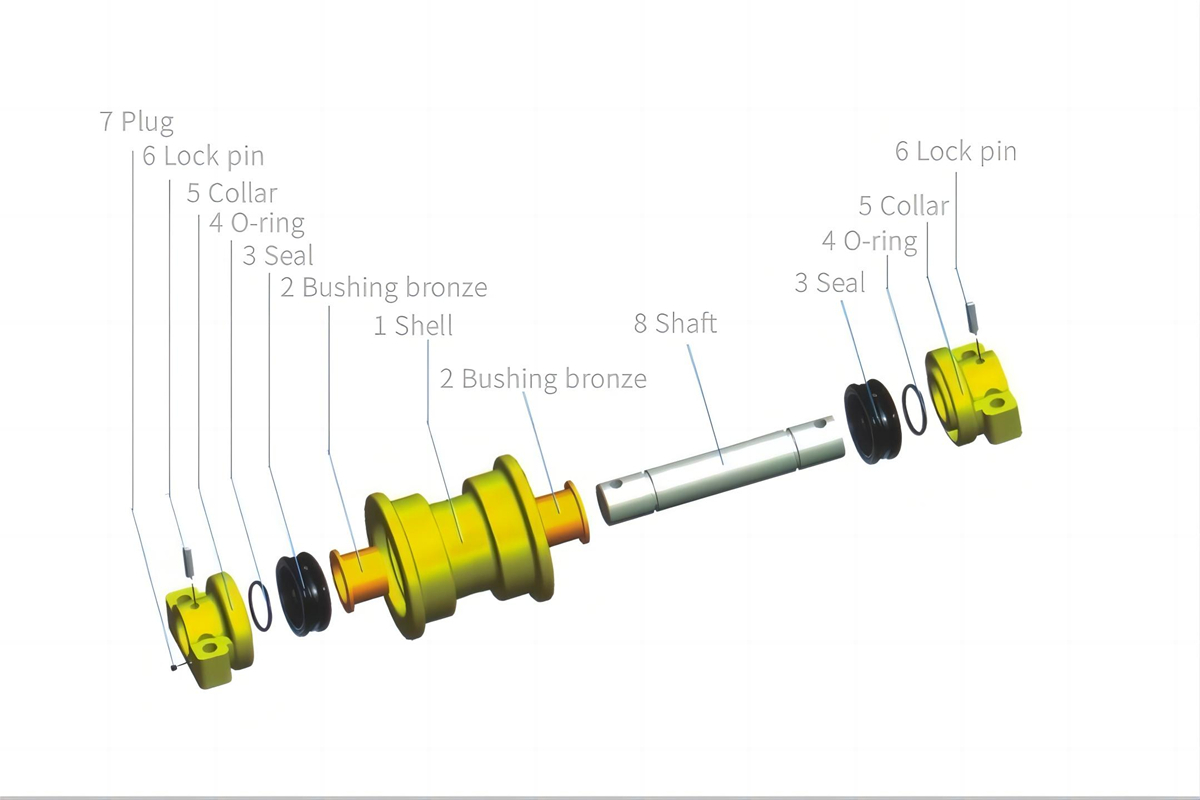

D7G Bulldozer Track Rollers 1181623 1248250 Fit For Caterpillar Part Number:

D7G Bulldozer Double Flange Track Roller Part Number:

BERCO CR2617, CR2617A, CR2617B

CATERPILLAR 1181623, 1248250, 1254178, 3235925, 3P1520, 3P6062, 4S9050, 4S9051, 6T9871, 9S0316

ITM A01070A1M00

LIEBHERR 5002787, 5603031, 7405220

D7G Bulldozer Single Flange Track Roller Part Number:

BERCO CR2617, CR2617A, CR2617B

CATERPILLAR 1181623, 1248250, 1254178, 3235925, 3P1520, 3P6062, 4S9050, 4S9051, 6T9871, 9S0316

ITM A01070A1M00

LIEBHERR 5002787, 5603031, 7405220

The specific testing methods and standards for the wear resistance, sealing, and lubrication of bulldozer track rollers are as follows:

Wear Resistance Testing:

Wear resistance testing is one of the inspection items for track rollers, primarily assessing the wear performance through the measurement of wear quantity. The material used for track roller bodies typically includes 50Mn and 40Mn2. The main processes involve casting or forging, machining, and then heat treatment. The hardness of the wheel surface after quenching should reach HRC45 to HRC52 to enhance the wear resistance of the wheel surface.

Sealing Testing:

Sealing testing is one of the inspection items for bulldozer track rollers, primarily assessing sealing performance through air tightness testing.

Lubrication Testing.

how to correctly install and maintain bulldozer track rollers to extend their lifespan?

To properly install and maintain the bulldozer track rollers and increase their lifespan, the following steps and precautions should be followed:

Bulldozer track rollers are the core components of the bulldozer's tracked chassis, and their performance directly affects the reliability and working efficiency of the entire machine. Therefore, when selecting track rollers, ensure their quality meets the required standards to minimize failures and extend service life.

Regularly check the wear of the bulldozer track rollers and their related components (such as idlers and carrier rollers), especially at the flange and groove areas. If uneven wear is detected, it may be caused by "rail biting," necessitating timely analysis and corrective measures. Additionally, lubrication is critical, as poor lubrication can lead to frequent bearing wear and subsequently damage the track rollers.

When installing bulldozer track rollers, use specialized tools and ensure that the mounting bolts are secured properly. Similarly, when disassembling, specialized tools should be employed to avoid damaging components.

To extend the lifespan of the bulldozer track rollers, it is possible to swap the positions of the front and rear track rollers, but it is essential to maintain the original positions of the single and double-sided track rollers on the walking frame.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported