Dozer Undercarriage Parts

CR4293 6T0067 9W5586 Dozer Bottom Roller Single Flange Fit For Caterpillar D7H

Crafted with precision and engineered with meticulous attention to detail, this CR4293 6T0067 9W5586 Dozer Bottom Roller Single Flange Fit For Caterpillar D7H guarantees smooth operation and enhanced productivity throughout your construction projects. Unleash the power of reliability and elevate your Caterpillar D7H to new heights with this impeccable single flange dozer bottom roller.

CR4293 6T0067 9W5586 Dozer Bottom Roller Single Flange Fit For Caterpillar D7H also compatible machine below:

973 66G-788-UP 973 LGP 86G-223-UP 973 LGP 91L-165-UP

Part Number:

BERCO CR4293

CATERPILLAR 6T0067, 9W5586

ITM A01079H1M00

KOMATSU ALL MAKES ZZYR0022

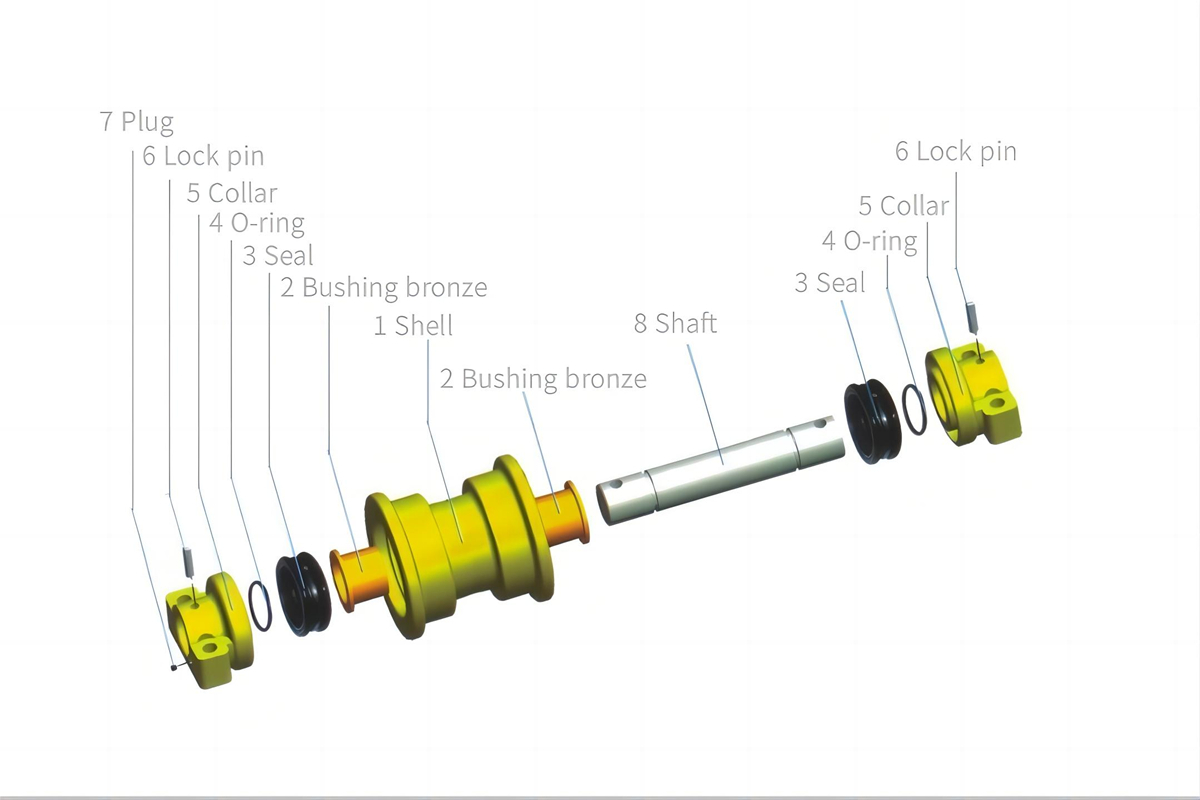

To better prevent lubricant leakage and the entry of external contaminants, we have designed the sealing system for the bulldozer bottom roller with multiple factors and components in mind.

Selecting Appropriate Sealing Components:

We use floating oil seals and O-rings to prevent lubricant leakage and external contamination. The floating oil seal effectively prevents the escape of lubricant while blocking mud and water from entering the interior of the roller. Additionally, O-rings are used between the spindle and the outer and inner covers to ensure a good sealing effect.

Installing and Maintaining Sealing Components:

It's essential to ensure that the O-rings between the retaining ring and the shaft are in good condition and undamaged to avoid issues with oil leakage caused by faulty or damaged O-rings.

For bulldozer owners, preventing lubricant leakage from the dozer bottom roller and blocking external contaminants can be achieved by regularly checking the contact condition of the floating seals to ensure good contact, thus preventing leakage due to poor contact.

Moreover, it is advisable to use appropriate lubricants. Select the right lubricant based on the working environment and temperature. For instance, if the working environment is characterized by high temperatures, consider using grease instead of oil to prevent sealing issues arising from excessively high oil temperatures. Additionally, choose the type of grease with a suitable consistency, such as lower consistency grease (with a smaller grade), to accommodate high-temperature environments.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported