Dozer Undercarriage Parts

Bulldozer Track Roller CR2615 1181625 1248253 Fit For Caterpillar D7R D7G D7F

Impeccably crafted with precision engineering, the Bulldozer Track Roller CR2615 1181625 1248253 Fit For Caterpillar D7R D7G D7F offers unparalleled durability and exceptional performance. Dominate the job site with confidence, as this roller ensures optimal traction and smooth maneuverability, guaranteed to elevate your bulldozer's capabilities to new heights.

Bulldozer Track Roller CR2615 1181625 1248253 Fit For Caterpillar D7R D7G D7F compatible with machine below:

CATERPILLAR

571F, 571G , 572F, 572G , 973 , 973 LGP, 977K , 977L crawler loader track roller, D7F 6, D7G, D7H , D7R bulldozer track roller

JOHN DEERE

950C, 950C LGP bulldozer track roller

LIEBHERR

LR641, PR741, PR741B, PR741C, PR742 , PR742M , PR744L , PR744LGP, SR741 bulldozer track roller

Bulldozer track roller fit for D7H D7G D7R part number:

BERCO: CR2615, CR2615A, CR2615B

CATERPILLAR: 118-1625, 124-8253, 125-4179, 188-5597, 323-5928, 3P1521, 3P6063, 6P9885, 6T9867, 8S2933, 9S0317

ITM: B01070A1M00

LIEBHERR: 5002788, 5603037

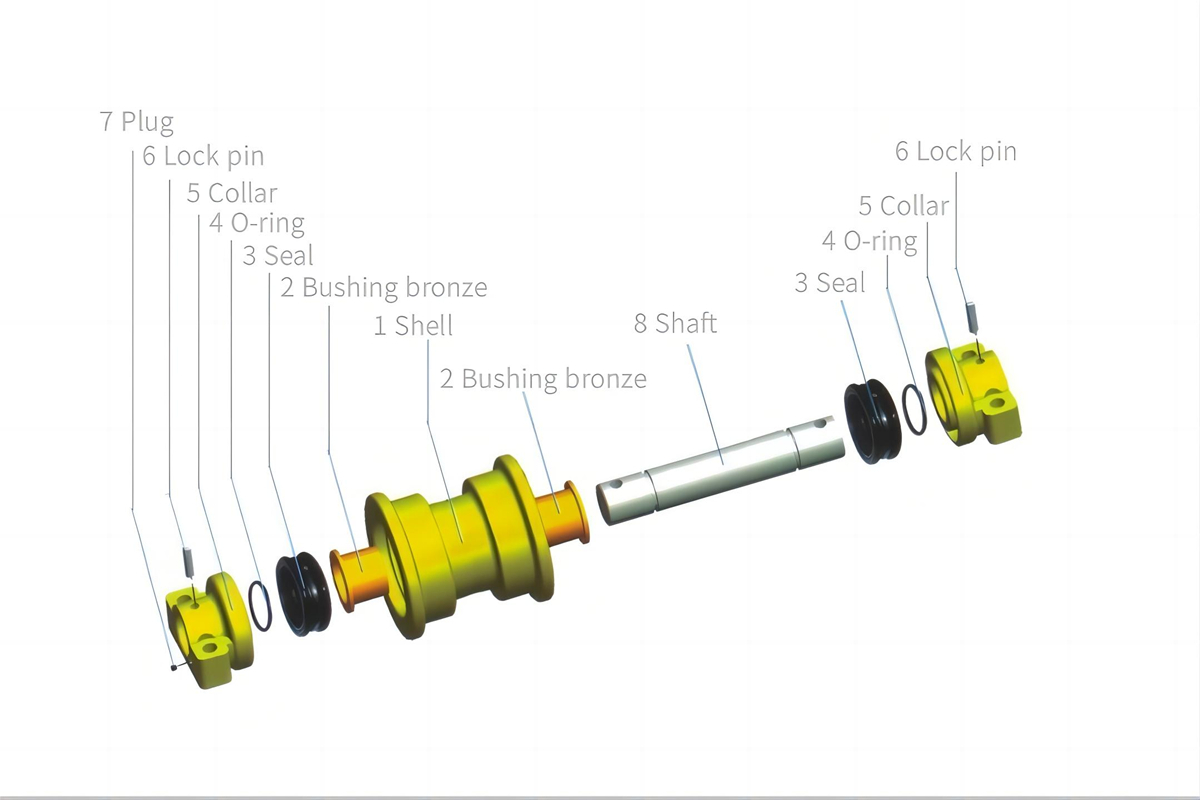

In addition to using high-quality raw materials and strict heat treatment processes, we have also improved the structural design of the bulldozer track roller to enhance its quality. For high-powered bulldozers, we have modified the design of the floating seal to effectively prevent oil leakage.

Regarding the lubrication and sealing of the bulldozer track roller, we ensure that the track rollers are properly lubricated during manufacturing or rebuilding, which helps avoid the need for frequent lubrication during use. Additionally, we utilize appropriate seals and other components to prevent moisture and other contaminants from entering the interior of the roller, thus extending its lifespan.

From the perspective of bulldozer owners, the quality and lifespan of the bulldozer track roller can be improved in the following ways:

Choose High-Quality Bulldozer Track Rollers: Select high-quality track rollers that meet design requirements, including nominal diameter, width, material, weight, and pre-tensioning parameters, all of which should comply with standards. Furthermore, choose bulldozer track rollers designed to minimize friction, as this can enhance productivity and extend the overall operating efficiency of the equipment.

Regular Maintenance: Implementing a regular maintenance schedule is crucial for ensuring the long-term, stable operation of track rollers. For instance, check for signs of wear on the bulldozer track rollers before operation and make necessary adjustments or replacements promptly. Additionally, for the floating walking system's track rollers, maintaining consistent contact with the track can increase the ground contact area, improving traction and reducing impact loads on the walking system.

Adapt to Different Working Conditions: Select appropriate bulldozer track roller models based on different working environments. For example, when working on soft or wet ground, wider track shoes can be chosen to provide better stability. Additionally, for high-load operations in harsh conditions, track systems with higher wear resistance can be selected.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported