Hydraulic Breaker Chisel

Rock Breaker Chisels are engineered for rugged performance in the challenging field of rock and concrete breaking. Crafted from high-strength alloy steel and subjected to advanced heat treatment processes, these chisels embody durability and wear resistance. Precision machining ensures a perfect fit for various breaker models, guaranteeing optimal performance.

1、instruction

Our chisels excel in the demanding tasks of excavating and demolishing, showcasing exceptional hardness and toughness. Whether breaking through solid rock or concrete structures, these chisels maintain their sharpness and integrity, ensuring efficient and reliable operation. The cutting-edge design minimizes downtime, enhances productivity, and extends the overall lifespan of the chisel.

2、Key Features:

----High-strength alloy steel construction for durability

----Advanced heat treatment for wear resistance

----Precision machining for a perfect fit

----Exceptional hardness and toughness for demanding tasks

----Cutting-edge design for enhanced productivity and longevity

----Choose our Rock Breaker Chisels for a powerful and reliable solution in your rock-breaking applications. Our commitment to quality and performance sets us apart as a trusted supplier in the industry.

3、Why Choose Us

Expertise in Heat Treatment:

Our Rock Breaker Chisels undergo a meticulous heat treatment process, ensuring optimal hardness and durability. This expertise not only enhances the wear resistance of our chisels but also contributes to their overall longevity, making them reliable partners in the most demanding rock-breaking applications.

Precision Machining Excellence:

Crafted with precision, our chisels undergo advanced machining techniques that guarantee dimensional accuracy and consistent performance. Our state-of-the-art machining facilities and skilled technicians ensure that each chisel meets the highest industry standards, providing you with a product that excels in both efficiency and reliability.

Customized Solutions:

Understanding the diverse needs of our clients, we offer customizable solutions in both heat treatment specifications and machining details. This flexibility allows us to tailor our Rock Breaker Chisels to specific requirements, ensuring optimal performance in various operating conditions.

Stringent Quality Control:

Our commitment to quality extends beyond the production floor. Rigorous quality control measures are implemented throughout the manufacturing process, from material selection to the final inspection. This ensures that every Rock Breaker Chisel that leaves our facility adheres to the strictest quality standards.

Proven Performance:

Backed by extensive testing and real-world application, our Rock Breaker Chisels have demonstrated exceptional performance in diverse environments. Customers worldwide trust our products to deliver consistent results, making us a preferred choice in the industry.

4、product specifications

|

model |

Diameter |

length |

|

SB10 |

40 |

|

|

SB20 |

45 |

500 |

|

SB30 |

53 |

600 |

|

SB35 |

60 |

600 |

|

SB40 |

68 |

700 |

|

SB43 |

75 |

750 |

|

SB45 |

85 |

850 |

|

SB50 |

100 |

1000 |

|

SB60 |

125 |

1150 |

|

SB81N/SB70 |

135 |

1250 |

|

SB81 |

140 |

1250 |

|

SB100 |

150 |

1400 |

|

SB121 |

155 |

1400 |

|

SB130/SB131 |

165 |

1500 |

|

SB140/SB141 |

165 |

1500 |

|

SB151 |

175 |

1600 |

|

HB100 |

55 |

600 |

|

HB200 |

70 |

700 |

|

HB700 |

104 |

1000 |

|

HB1G |

36 |

400 |

|

HB2G |

45 |

500 |

|

HB3G |

60 |

600 |

|

HB5G |

70 |

700 |

|

HB8G |

90 |

900 |

|

HB10G |

105 |

1000 |

|

HB15G |

120 |

1100 |

|

HB20G |

135 |

1250 |

|

HB30G |

150 |

1400 |

|

HB40G |

160 |

1400 |

|

HB50G |

180 |

1600 |

|

HB1200 |

140 |

1250 |

|

F3 |

52 |

600 |

|

F4 |

60 |

600 |

|

F5 |

68 |

700 |

|

F6 |

75 |

750 |

|

F9 |

90 |

900 |

|

F12 |

105 |

1000 |

|

F19 |

120 |

1100 |

|

F22 |

135 |

1250 |

|

F27 |

140 |

1250 |

|

F35 |

150 |

1400 |

|

F45 |

165 |

1500 |

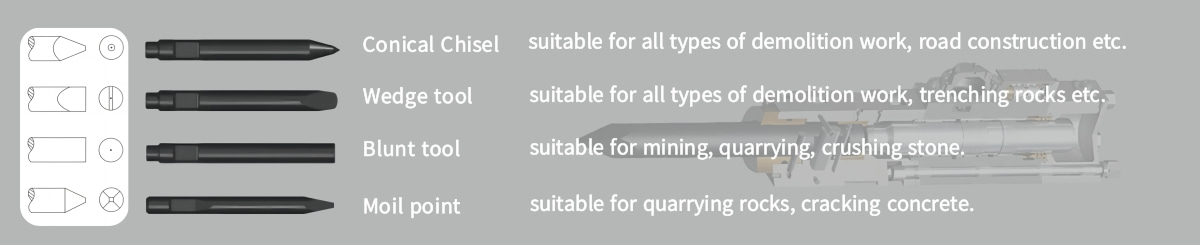

5、How to select suitable chisel

6、FAQ

Terms & Conditions of Ordering:

① Payment Terms: T/T (Telegraphic Transfer)

② Delivery Term: Based on order quantity, normally it takes 25 days for production. Only 2 or 5 days if we have stock on your request size.

③ Transportation: Sample order: we suggest Courier express or by air. Bulk order: we suggest by air or by sea.

④ Quality & Service:

A. There will be strict inspection and testing for every order before shipping out.

B. Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded) through WhatsApp/Wechat: + 86 18850110101

⑤Q: Can I place a small order initially?

A: Yes, certainly.

⑥Q: If we decide to change the size of the product, can you provide the seal kit for the new size?

A: Yes, just send us the machine model, part number, and the updated size details. We can make it for you.

⑦Q: Do you support OEM or not?

A: Certainly, we support OEM, or as per your requirements.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported