Hydraulic Breaker Chisel

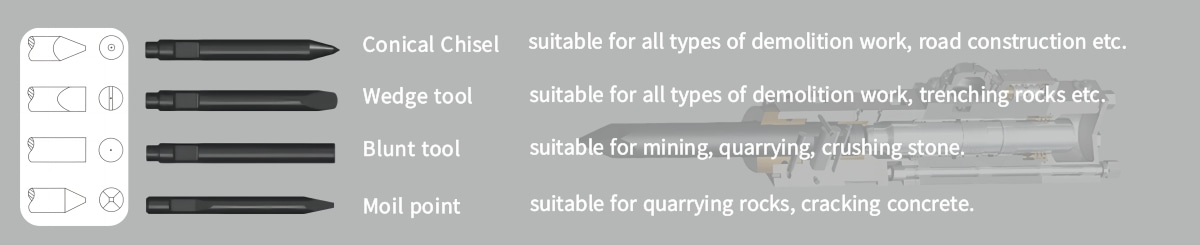

The design of hydraulic breaker chisels can vary to meet different job requirements, with different shapes and sizes of chisel points available. These chisels are typically made from high-strength, wear-resistant materials to ensure they can withstand the demands of high-pressure hydraulic systems and provide long-lasting performance. The choice of chisel often depends on the nature of the project and the type of material being processed.

1、Introduction

Our Hydraulic Breaker Chisels are crafted using premium-grade alloy steel, ensuring exceptional strength, durability, and wear resistance for prolonged use in demanding applications.

Our production process involves advanced CNC machining and heat treatment techniques, guaranteeing precision engineering and consistent performance. Each chisel undergoes strict quality control checks, and all QC data is recorded for traceability and quality assurance.

One of our core strengths is providing a wide range of Hydraulic Breaker Chisels, available in various shapes and sizes to suit different breaking requirements and geological conditions. Whether it's for rock excavation, concrete demolition, or other tasks, our chisels deliver efficient and reliable results.

Apart from top-notch product quality, we pride ourselves on offering competitive prices without compromising on performance. Our cost-effective Hydraulic Breaker Chisels ensure excellent value for money and enhance the overall cost-effectiveness of your projects.

Furthermore, we understand the importance of timely deliveries to meet your project timelines. With a well-organized logistics system, we ensure prompt shipping and delivery to your location, anywhere in the world.

As a customer-centric company, we prioritize delivering exceptional service. Our dedicated and experienced team is always ready to assist you with any inquiries, technical support, or after-sales service, ensuring a seamless and satisfying experience with our Hydraulic Breaker Chisels.

2、how to select a suitable chisel

3、product specifications

|

model |

Diameter |

length |

|

SB10 |

40 |

|

|

SB20 |

45 |

500 |

|

SB30 |

53 |

600 |

|

SB35 |

60 |

600 |

|

SB40 |

68 |

700 |

|

SB43 |

75 |

750 |

|

SB45 |

85 |

850 |

|

SB50 |

100 |

1000 |

|

SB60 |

125 |

1150 |

|

SB81N/SB70 |

135 |

1250 |

|

SB81 |

140 |

1250 |

|

SB100 |

150 |

1400 |

|

SB121 |

155 |

1400 |

|

SB130/SB131 |

165 |

1500 |

|

SB140/SB141 |

165 |

1500 |

|

SB151 |

175 |

1600 |

|

HB100 |

55 |

600 |

|

HB200 |

70 |

700 |

|

HB700 |

104 |

1000 |

|

HB1G |

36 |

400 |

|

HB2G |

45 |

500 |

|

HB3G |

60 |

600 |

|

HB5G |

70 |

700 |

|

HB8G |

90 |

900 |

|

HB10G |

105 |

1000 |

|

HB15G |

120 |

1100 |

|

HB20G |

135 |

1250 |

|

HB30G |

150 |

1400 |

|

HB40G |

160 |

1400 |

|

HB50G |

180 |

1600 |

|

HB1200 |

140 |

1250 |

|

F3 |

52 |

600 |

|

F4 |

60 |

600 |

|

F5 |

68 |

700 |

|

F6 |

75 |

750 |

|

F9 |

90 |

900 |

|

F12 |

105 |

1000 |

|

F19 |

120 |

1100 |

|

F22 |

135 |

1250 |

|

F27 |

140 |

1250 |

|

F35 |

150 |

1400 |

|

F45 |

165 |

1500 |

4、FAQ

Terms & Conditions of Ordering:

① Payment Terms: T/T (Telegraphic Transfer)

② Delivery Term: Based on order quantity, normally it takes 25 days for production. Only 2 or 5 days if we have stock on your request size.

③ Transportation: Sample order: we suggest Courier express or by air. Bulk order: we suggest by air or by sea.

④ Quality & Service:

A. There will be strict inspection and testing for every order before shipping out.

B. Our sales team and Technical Support will response for your question within 24 hours (Holidays Excluded) through WhatsApp/Wechat: + 86 18850110101

⑤Q: Can I place a small order initially?

A: Yes, certainly.

⑥Q: If we decide to change the size of the product, can you provide the seal kit for the new size?

A: Yes, just send us the machine model, part number, and the updated size details. We can make it for you.

⑦Q: Do you support OEM or not?

A: Certainly, we support OEM, or as per your requirements.

5、Our service

Pre-sale support:

a. Develop customized projects based on client needs.

b. Create and manufacture products tailored to specific client requirements.

c. Provide training for technical personnel.

During-sale assistance:

a. Assist clients in selecting reliable freight forwarders in advance of delivery.

b. Aid clients in formulating problem-solving strategies.

Post-sale services:

a. Guide clients in preparing construction plans.

b. Oversee the installation and debugging of equipment.

c. Conduct training sessions for first-line operators.

d. Perform equipment inspections.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported