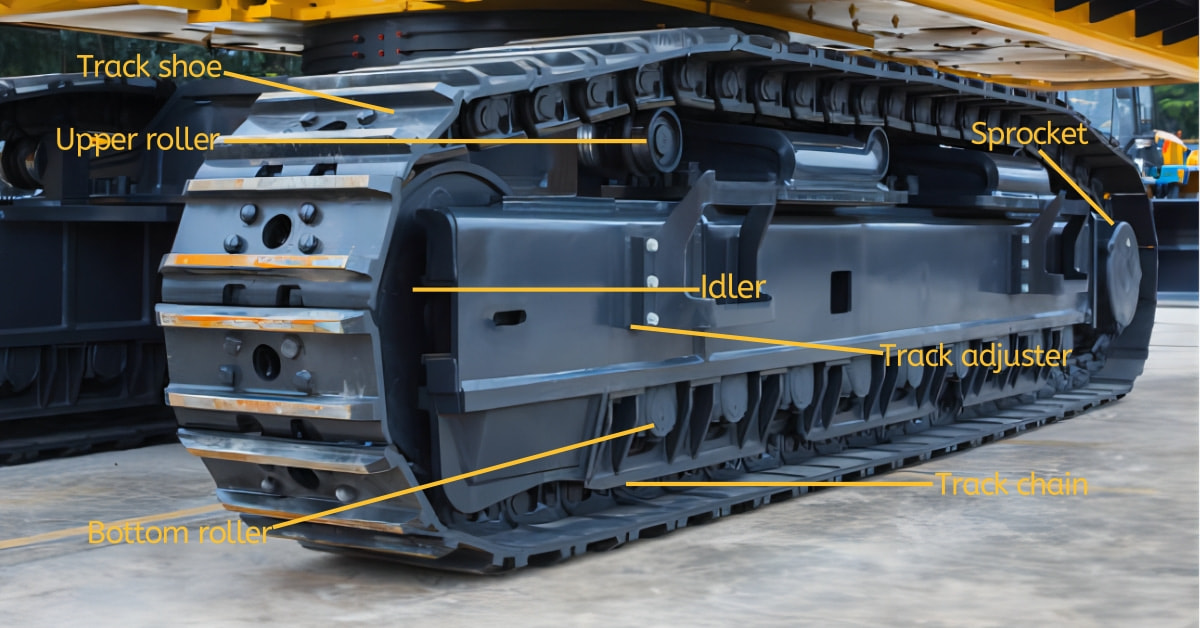

Excavator Undercarriage Parts

In the world of construction and heavy machinery, the excavator plays a pivotal role. Its efficiency and performance are vital to the success of any construction project. One of the critical components that contribute to the smooth operation of an excavator is the idler. Idlers are essential in maintaining track tension, distributing the load evenly, and ensuring the machine's stability, making them indispensable for efficient operation.

An idler is a crucial component in the undercarriage of an excavator, responsible for guiding and maintaining the track chain's tension. It helps in distributing the machine's weight, reducing the load on the track links, and ensuring smooth movement.

Idlers come in various types, including front idlers, rear idlers, and tension idlers. Each type serves a specific purpose, contributing to the overall functionality and efficiency of the excavator.

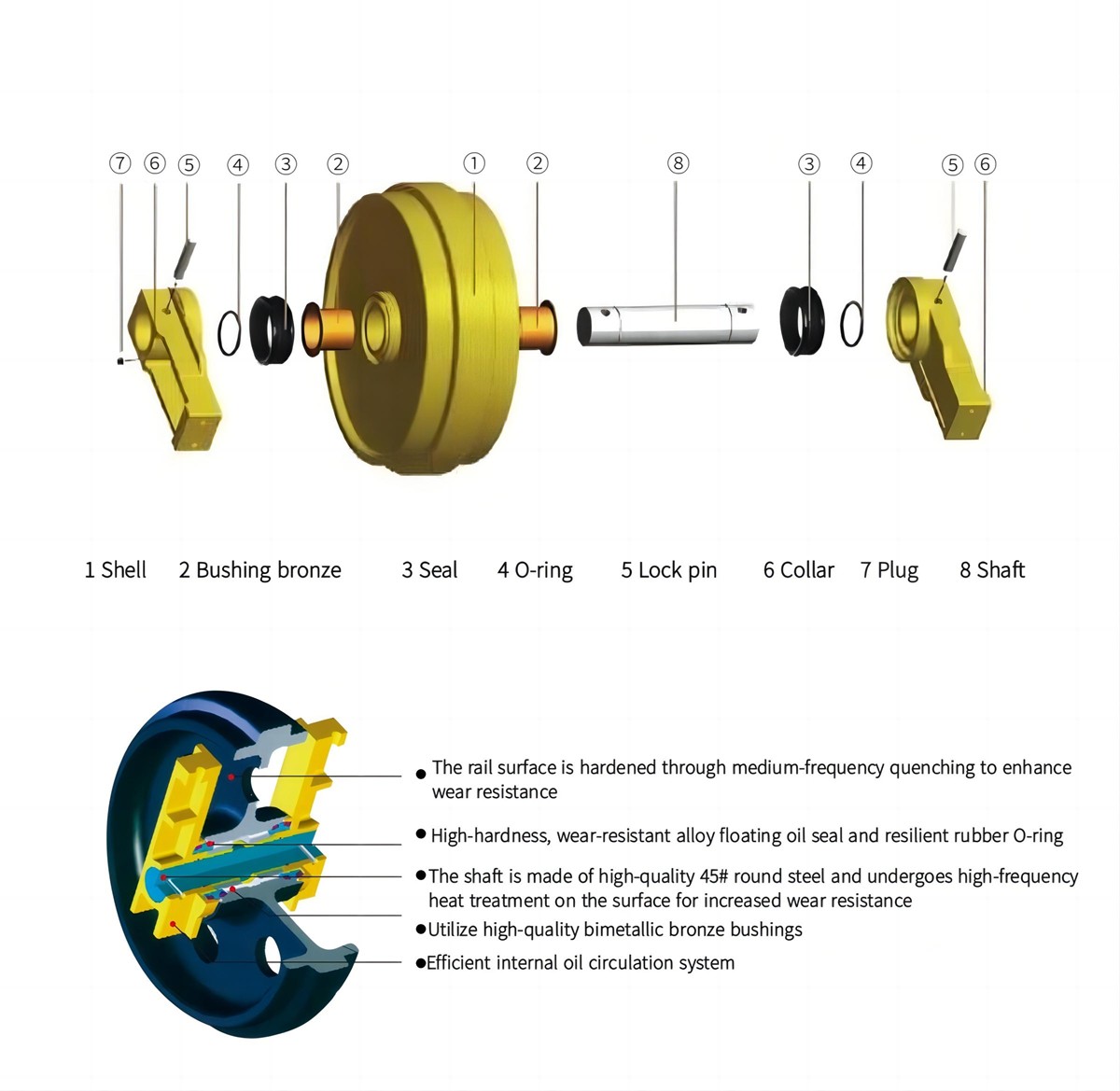

The idler comprises several components, including the shell, shaft, bearing, and seals. These parts work together to provide the necessary support and stability to the track system.

Idlers are typically made from high-strength steel or cast iron, materials known for their durability and resistance to wear and tear. The choice of material plays a crucial role in determining the idler's lifespan and performance.

The manufacturing process of idlers involves precision casting, machining, and heat treatment. Each step is carefully monitored to ensure the final product meets the stringent quality standards required for heavy machinery.

Quality control is paramount in the production of idlers. Rigorous testing, including hardness tests, load-bearing tests, and wear resistance evaluations, ensures that each idler can withstand the harsh conditions of construction sites.

Over time, idlers can show signs of wear, such as uneven surfaces, cracks, or excessive movement. These indicators suggest that the idler may need attention.

An idler should be replaced when it shows significant wear or when its performance starts to decline. Ignoring these signs can lead to more severe damage to the undercarriage and other components.

Failing to replace a worn idler can result in track misalignment, increased wear on track links and rollers, and even machine instability. This can lead to costly repairs and extended downtime.

As a seasoned manufacturer of excavator undercarriage parts with years of industry experience, we pride ourselves on delivering exceptional quality and reliability. Here are several reasons why you should choose us for your excavator idler requirements:

Expert Craftsmanship: Our production processes are backed by years of expertise, ensuring that every excavator idler is crafted with precision and attention to detail. We utilize advanced manufacturing techniques to guarantee the highest quality standards.

Premium Material Selection: We prioritize the selection of high-quality materials that enhance the durability and performance of our products. Our idlers are designed to withstand harsh operating conditions, ensuring longevity and reliability in the field.

Comprehensive Product Range: We offer a wide variety of excavator idler models, catering to different makes and models of excavators. Our extensive inventory ensures that you can find the right part for your specific needs without delay.

Timely Delivery: We understand the importance of minimizing downtime in your operations. Our efficient logistics and inventory management systems enable us to provide prompt shipping, ensuring that you receive your products on time.

Outstanding After-Sales Support: Our commitment to customer satisfaction extends beyond the sale. We offer excellent after-sales service, providing technical support and assistance to ensure that our products meet your expectations and operational needs.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported