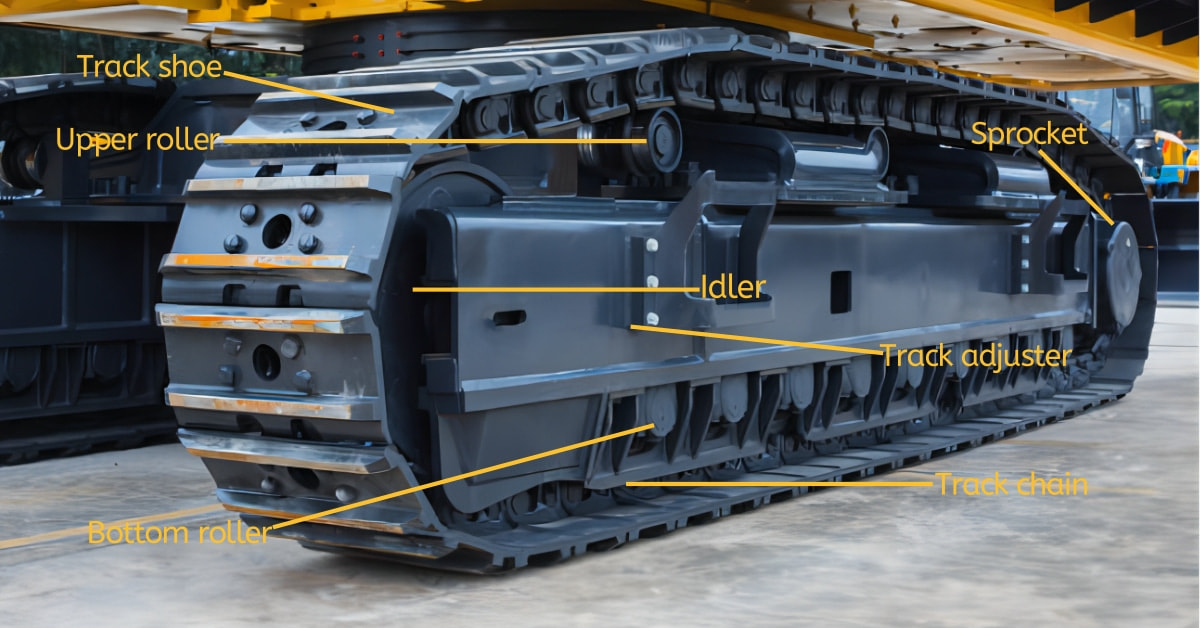

Excavator Undercarriage Parts

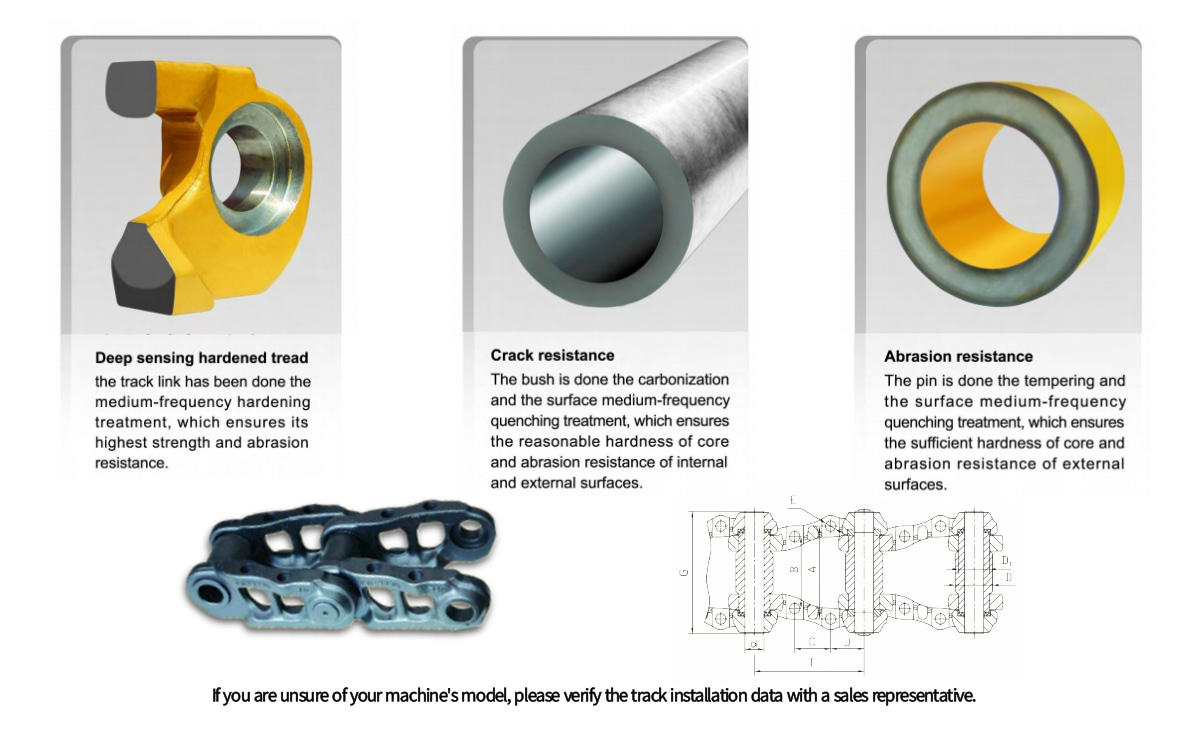

Excavator Track Link Assembly is a crucial component of the undercarriage system in excavators. It connects the track shoes and provides the necessary support and stability for the machine's movement.

Material Selection:

Manufacturing Process:

Design Considerations:

What are the specific steps and precautions for correctly installing and removing the excavator track link assembly?

The specific steps and precautions for correctly installing and removing the excavator track link assembly are as follows:

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported