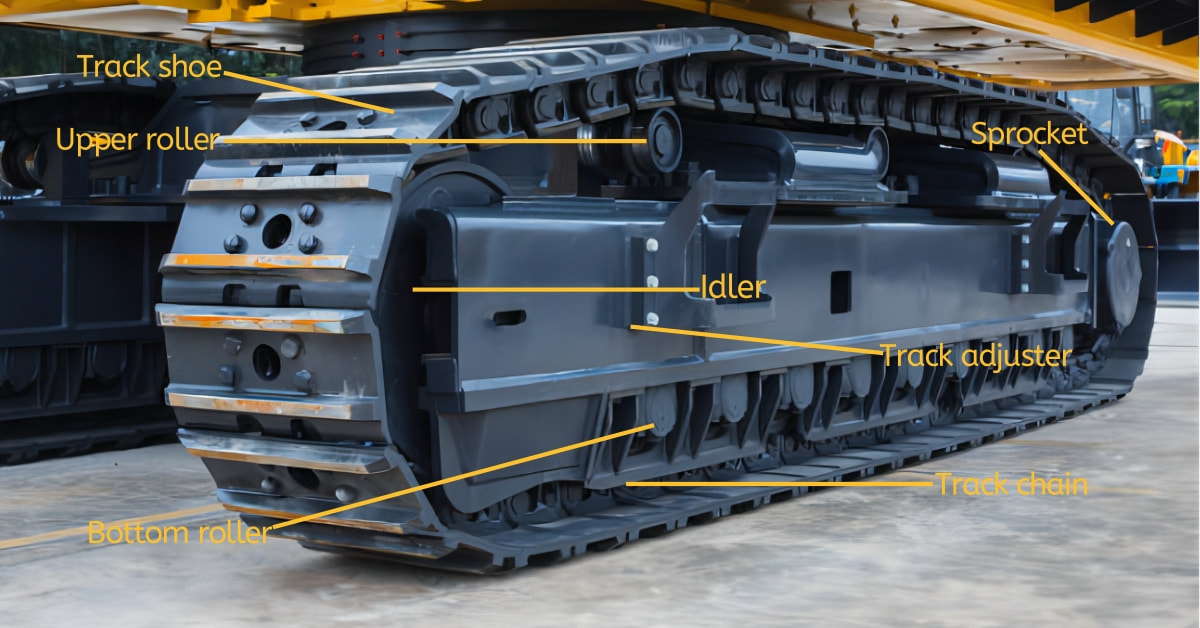

Excavator Undercarriage Parts

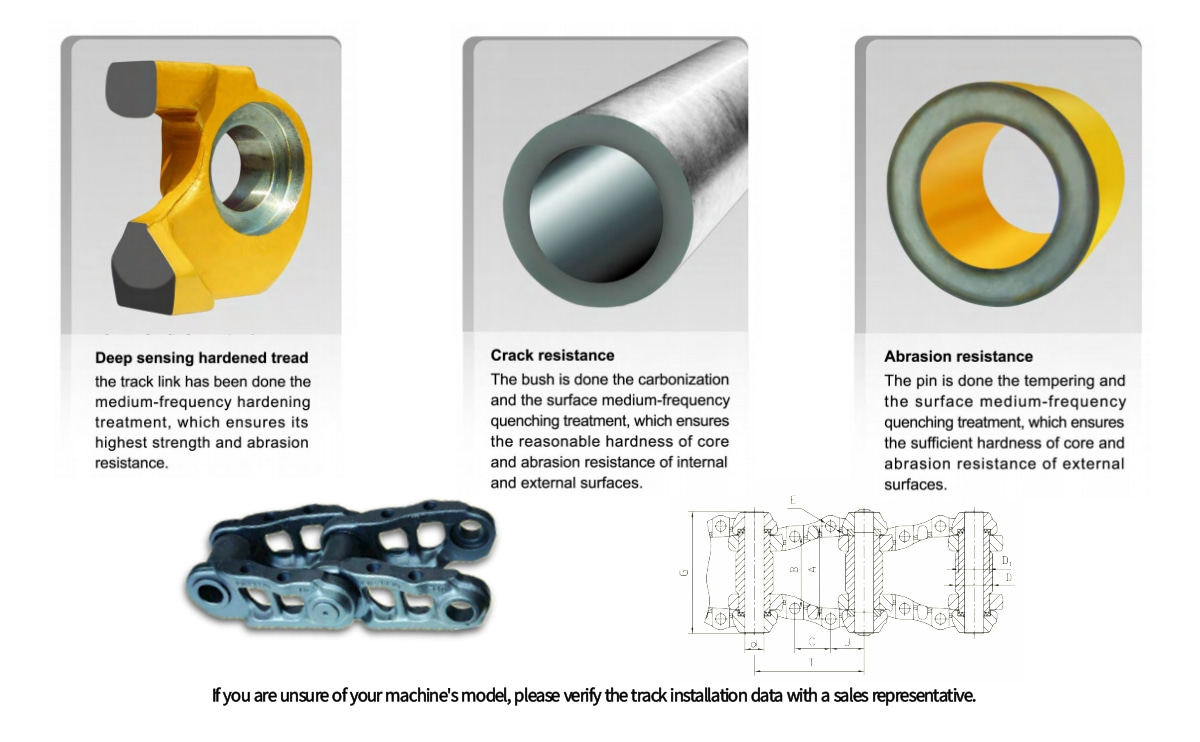

Experience the ultimate in durability and performance with our top-of-the-line Excavator Track Link. Crafted with precision engineering and exceptional materials, this track link is designed to withstand the toughest of conditions. Its seamless construction ensures seamless operation, providing unparalleled stability and longevity for your excavator.

| Material | 40MN2/35Mnbh |

| Finish | Smooth |

| Colors | Black or yellow/Customized |

| Technique | Forging /casting |

| Hardness | HRC37-49 |

| Process | Heat Treatment |

| Delivery Time | Within 15-30 days after payments |

| Package | Wooden pallets/boxes/plywood pallets/cartons |

Model OEM Part No

E12OB 990648 Track Chain For CAT Excavator

E200B 096-4301 Track Link For CAT Excavator

E311 4I7479 Track Chain For CAT Digger

E312 990648 Track Chain

E315 1028124 Track Chain

E320 9W9353 Track Chain

E325 6Y0854 Track Chain

E330 6Y2755 Track Chain

PC60-1 201-32-00113 Track Chain For Komatsu Excavator

PC60-3/5 201-32-00131 Track Link For Komatsu Excavator

PC60-6 201-32-00200 Track Chain Assemblies

PC60-7 201-32-00300 Track Link Assembly

PC100-1/2 202-32-00116 Track Chain

PC100-3 202-32-00131 Track Chain

PC100-5 202-32-00201 Track Chain

PC100-6 202-32-00202 Track Chain

PC120-1/2 202-32-00131 Track Chain

PC120-3 202-32-00011 Track Chain

PC120-5/6 202-32-00101 Track Chain

PC200-1/2 205-32-00031 Track Chain

PC200-3 205-32-00051 Track Chain

PC200-5/6 20Y-32-00013 Track Chain

PC200-7 20Y-32-00300 Track Chain

PC220-1/2 206-32-00011 Track Chain

PC220-3 206-32-00032 Track Chain

PC220-5/6 206-32-00103 Track Chain

PC300-1 207-32-00010 Track Chain

PC300-2 207-32-00031 Track Chain

PC300-3/5 207-32-00100 Track Chain

PC300-6 207-32-00300 Track Chain

PC300-7 207-32-00310 Track Chain

PC400-1 208-32-00011 Track Chain

PC400-5 208-32-00101 Track Chain

PC400-6 208-32-00300 Track Chain

EX60 9096710 Track Chain For Hitachi Excavator

EX60-2/3 9096710 Track Links For Hitachi Excavator

EX60-5 9156478 Track Chain Assemblies For Hitachi Excavator

EX100 9091948 Track Chain

EX100-2/3 9092929 Track Chain

EX100-5 9143278 Track Chain

EX120-1 9091951 Track Chain

EX120-2/3 9092932 Track Chain

EX120-5 9138747 Track Chain

EX200-1 9066724 Track Chain

EX200-2/3 9092517 Track Chain

EX200-5 9135631 Track Chain

EX220 9093029 Track Chain

EX220-2/3 9093029 Track Chain

EX220-5 9180319 Track Chain

EX270-1/2 9070645 Track Chain

EX270-5 9180884 Track Chain

EX300-1/2/3 9070645 Track Chain

EX300-5 9156481 Track Chain

EX330-5 9156481 Track Chain

EX400-2/3 9133225 Track Chain

EX400-5 9133225 Track Chain

SK60 24100N6311F2 Track Chain

SK120 24100J12245F5 Track Chain

SK200 24100J11338F2 Track Chain

SK300 24100J15218F2 Track Chain

DH200 2272-9004 Track Chain

DH220 2272-1025 Track Chain

DH280 2272-6047 Track Chain

R200 5601354 Track Chain

R210 81EM-20010 Track Chain

R290 175-8822 Track Chain

To ensure the optimal performance of excavator track links, regular inspection and lubrication are key steps. Here is a detailed inspection and lubrication procedure:

Visual Inspection:

First, regularly check the appearance of the chains for any signs of cracks, wear, or corrosion. These damages could lead to chain breakage or functional failure.

Wear Assessment:

Inspect the wear condition of each link in the chain, especially at the joints and between the links. Severe wear may require the replacement of new chain components.

Grease Condition:

Check whether the grease on the chains is sufficient and evenly distributed. Insufficient grease can lead to excessive wear and damage to the chains.

Choose the Right Lubricant:

Select an appropriate lubricant based on the working environment and load conditions of the chains. Generally, for heavy mining equipment, high-viscosity lubricating oil is recommended to provide better protection and extend service life.

Lubrication Frequency:

Set the lubrication frequency according to the manufacturer's recommendations and actual usage conditions. Typically, lubricating after a certain number of operating hours (e.g., every 50 hours) is common practice.

Lubrication Method:

Use either a manual or automatic lubrication system. An automatic lubrication system can precisely control the distribution of the lubricant through an electronic control module, improving efficiency and reducing maintenance costs.

Clean the Chains:

Thoroughly clean the chains before lubrication to remove old grease and other contaminants, ensuring that the new grease can effectively cover and protect the chains.

Diagnose Lubrication System Issues:

If insufficient lubrication or declining lubricant performance is detected, check all parts of the lubrication system, including pumps, lines, and distributors, to identify the problem and repair it promptly.

Regular Maintenance Plan:

Develop and adhere to a detailed annual maintenance plan, including non-destructive testing and other preventive maintenance measures, to reduce emergency downtime and extend equipment lifespan.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported