Excavator Undercarriage Parts

With its advanced design and superior materials, our Excavator Bottom Roller guarantees optimal performance and enhanced productivity for your construction projects. Trust in our expertise and elevate your excavating experience to new heights.

----Key Features of Excavator Bottom Roller:

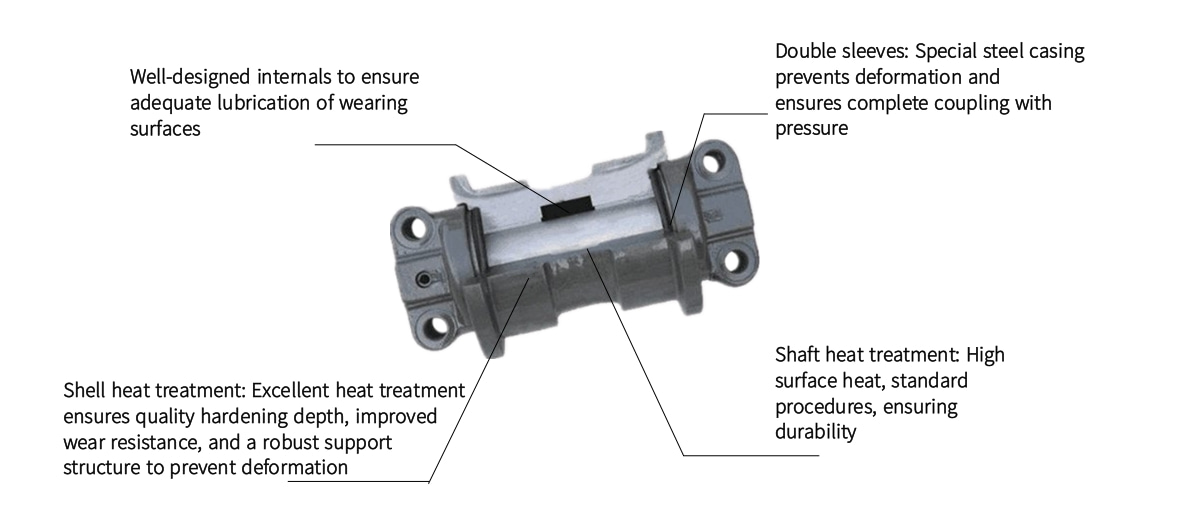

1. Superior Material: Our excavator bottom roller is meticulously crafted using high-quality materials that ensure durability and longevity. Manufactured from premium-grade steel, it is capable of withstanding heavy loads and extreme working conditions.

2. Precise Manufacturing: The bottom roller undergoes advanced processing techniques, including precision machining and heat treatment. This process enhances its structural integrity, allowing for smooth and efficient operation even in the most demanding terrains.

3. Rigorous Quality Control: To guarantee top-notch quality, each bottom roller undergoes meticulous quality inspections throughout the manufacturing process. Our team of experienced engineers conducts rigorous tests to ensure that every product meets the highest industry standards and surpasses customer expectations.

4. Enhanced Durability: With its robust construction, the excavator bottom roller showcases excellent resistance to wear and tear. It effectively minimizes maintenance costs while extending the overall lifespan of the undercarriage system, providing long-term reliability and peace of mind.

5. Versatility: Our bottom roller is compatible with various excavator models, making it a versatile choice for different construction applications. Whether you require it for road construction, landscaping, or any other heavy-duty operation, our bottom roller can adapt to meet your specific needs.

----Why Choose Us?

1. Competitive Prices: We understand the value of your hard-earned money. That's why we offer products at highly competitive prices, ensuring you get the best deals without sacrificing quality. Our pricing strategy guarantees that you receive excellent value for your investment.

2. Exceptional After-sales Service: Your satisfaction is our top priority. Our dedicated team of customer service professionals is committed to addressing your concerns promptly and effectively. From pre-sales inquiries to post-purchase assistance, we are here to ensure a hassle-free and enjoyable shopping experience for you.

3. Swift and Reliable Shipping: We know that waiting for your order can be frustrating. With our efficient shipping methods, we aim to deliver your products swiftly and reliably. Our strong partnerships with trusted logistics providers enable us to offer timely and secure deliveries to your doorstep. Rest assured, your purchases will arrive on time and in pristine condition.

4. Quality Assurance: We believe in providing only the best products to our customers. Our strict quality control measures ensure that every item meets our high standards before reaching your hands. You can trust that our curated selection of goods is of superior quality, built to last and satisfy your needs.

5. Extensive Product Range: From fashion and electronics to home essentials and everything in between, our diverse product range covers a wide array of categories. Discover the latest trends, find unique items, and fulfill your every need all in one place. With us, you have endless choices at your fingertips.

----FAQs - Quick Answers to Commonly Asked Questions

1.. What are the main benefits of using high-quality excavator bottom rollers?

Investing in high-quality excavator bottom rollers offers several advantages. Firstly, they enhance the overall performance and longevity of the machine, reducing downtime and maintenance costs. Secondly, superior materials and construction ensure optimal weight distribution, minimizing wear and tear on the undercarriage components. Lastly, they improve traction and stability, even in challenging terrains.

2. How do I know if my excavator bottom roller needs replacement?

Signs that indicate a worn-out or damaged bottom roller include excessive noise, uneven track wear, reduced machine stability, and decreased overall performance. Regular inspections and maintenance by qualified technicians are essential to identify and address any issues promptly.

3. What factors should I consider when purchasing excavator bottom rollers?

When buying excavator bottom rollers, it is important to consider the following factors:

- Compatibility: Ensure the rollers are compatible with the make and model of your excavator.

- Quality: Opt for rollers made from durable materials, such as forged steel or high-strength alloys, for extended service life.

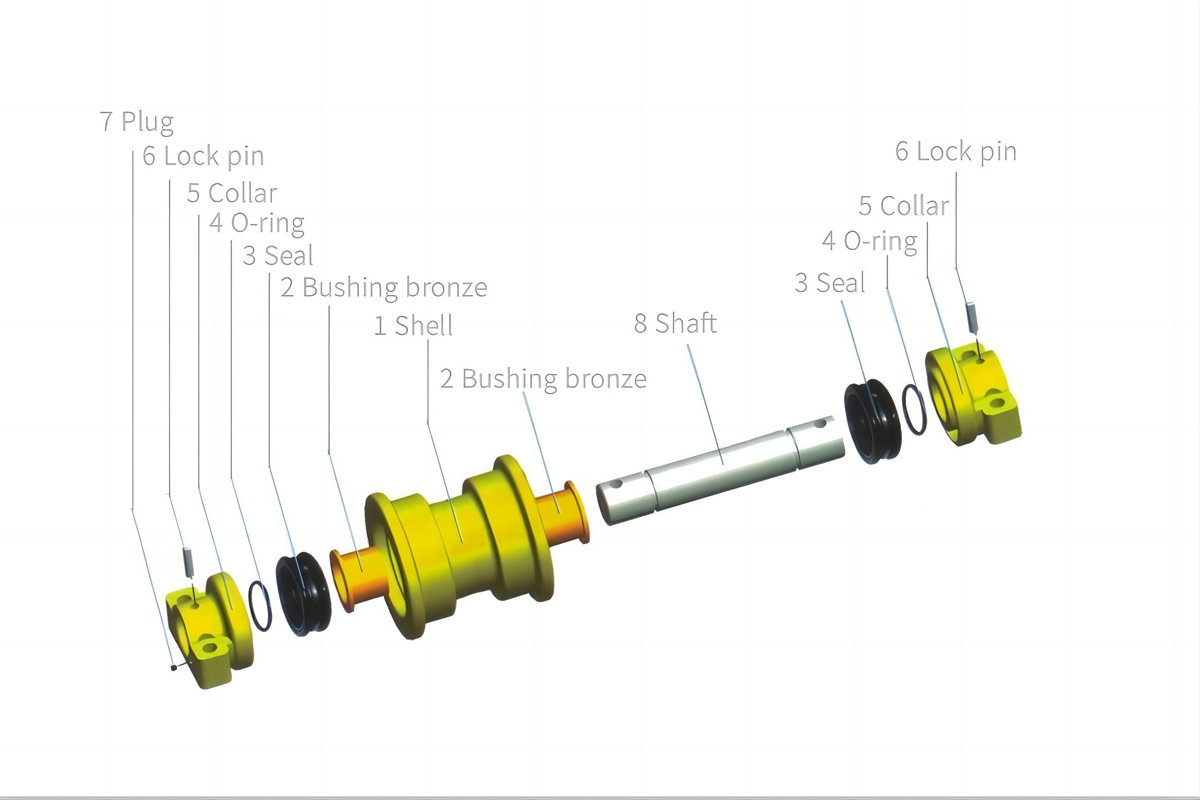

- Design: Look for rollers with precision engineering and advanced sealing systems to prevent contamination and maximize performance.

- Warranty: Choose rollers from reputable manufacturers that offer warranties, ensuring peace of mind and customer support.

4. How often should I replace excavator bottom rollers?

The replacement frequency of excavator bottom rollers depends on various factors, including workload, terrain conditions, and maintenance practices. However, it is generally recommended to inspect rollers regularly and replace them when signs of wear, damage, or decreased performance are evident.

6. Are there any maintenance tips to prolong the lifespan of excavator bottom rollers?

To extend the lifespan of your excavator bottom rollers, follow these maintenance tips:

- Keep the undercarriage clean and free from debris, dirt, and mud.

- Regularly lubricate the rollers to minimize friction and ensure smooth operations.

- Inspect the rollers for signs of wear or damage and take immediate action.

- Follow proper operating guidelines, such as avoiding excessive loads or operating in harsh environments for extended periods.

----Excavator Track Rollers Part number:

Model OEM Part No.

E311/312 151-9747/41-7346 Track Roller

E320/E200B 117-5045/8E-5034 Track Roller

E322 163-4145/61-9396 Track Roller

E325 117-5046/6Y-1057 Track Roller

E330 117-5047/6Y-2795 Track Roller

E450 863096/G643-00200B Track Roller

PC60-1/3 201-30-00050 Track Roller

PC60-5/6 201-30-00062 Track Roller

PC60-6 21W-30-00021 Track Roller

PC60-7 201-30-00292 Track Roller

PC100-1/2/3/5 203-30-00140 Track Roller

PC100-6/PC120-6 203-30-00220 Track Roller

PC120-1/2/3/5 203-30-00140 Track Roller

PC200-1/2 205-30-00172 Track Roller

PC200-3 20Y-30-00130 Track Roller

PC200-5/6 20Y-30-00012 Track Roller

PC200-7 20Y-30-00015 Track Roller

PC220-1/2 205-30-00172 Track Roller

PC220-3 20Y-30-00130 Track Roller

PC220-5/6 20Y-30-00012 Track Roller

PC300-1/2 141-30-00578 Track Roller

PC300-3 207-30-00130 Track Roller

PC300-5/6 207-30-00150 Track Roller

PC400-3/5 208-30-00210 Track Roller

EX60-1 9046234/9066207 Track Roller

EX60-2 9066970 Track Roller

EX60-3 9096970 Track Roller

EX60-5 9153152/9177016 Track Roller

EX100 9066508 Track Roller

EX100-2/3/5 9132600/9092522 Track Roller

EX120-1 9066508 Track Roller

EX120-2/3/5 9132600/9092522 Track Roller

EX200-1 9114617/9066510 Track Roller

EX200-2/3 9089173 Track Roller

EX200-5 9134243 Track Roller

EX220-1 9114618/9066509 Track Roller

EX220-2 9089173 Track Roller

EX220-3/5 9132602 Track Roller

EX270-1/2 9114682 Track Roller

EX270-5 9168173 Track Roller

EX300-1 9114619/9066690 Track Roller

EX300-2/3/5 9168173/9114682 Track Roller

EX400-1/2/3/5 4386648/9129347 Track Roller

SK100-1/SK120-1 24100N4042F2 Track Roller

K907B B90N0059F6 Track Roller

SK200-1 24100N5947F2 Track Roller

SK220-1 24100J11696F3 Track Roller

SK200-2/3 24100N5947F2 Track Roller

SK200-5/6 YN64D00013F1 Track Roller

SK300-1 24100N3856F3 Track Roller

SK330-6 LC64D00005F1 Track Roller

SH100/SH120 KNA0242/KNA0532 Track Roller

SH200 KRA1189 Track Roller

SH200 KRA1190 Track Roller

SH220 KBA0869 Track Roller

SH220 KBA0870 Track Roller

HD700 547-50800110 Track Roller

HD820 707-50800101 Track Roller

DH220 2270-1098 Track Roller

DH280/DH320 2270-9401A Track Roller

R200 E181-2002 Track Roller

R210 81EL-20020 Track Roller

R210LC-7 81N6-11010 Track Roller

R290 81E9-2002 Track Roller

R290LC-7 81N8-11010 Track Roller

EC210 1181-00020 Track Roller

EC240 1181-00020 Track Roller

EC290 1181-01011 Track Roller

EC360 1081-01820 Track Roller

EC460 1081-01820 Track Roller

Failing to promptly replace damaged excavator bottom roller can have the following impacts on the track chain, idlers, and sprockets:

Increased Wear:

The bottom roller endure significant alternating impact forces during the movement of the excavator. If a damaged idler wheel is not replaced in time, the contact between its outer edge and the track links will exacerbate wear, affecting the overall lifespan and efficiency of the entire track system. Additionally, premature wear failure of the bottom rollerl can lead to accelerated wear of the track chain.

Structural Damage:

The damage to the bottom roller not only affects its own performance but can also transfer increased friction and stress to other structural components, such as the idlers and srockets. In such cases, these components may develop cracks or fractures due to excessive loading.

Seal Failure:

Failure of the bottom roller seals can lead to lubricant leakage, which not only reduces lubrication effectiveness but may also allow moisture and other contaminants to enter the system, further accelerating corrosion and wear of other components.

Reduced Power Transmission Efficiency:

Damage to the excavator bottom roller can lead to decreased power transmission efficiency in the track drive system, thereby affecting the overall operational efficiency of the excavator. This includes performance during operations such as climbing and towing.

Safety Issues:

Long-term use of damaged excavator bottom roller can result in track instability, increasing safety risks during operation. This risk is particularly pronounced during high-speed travel or work in complex terrain.

Therefore, to ensure the normal operation of the excavator and extend the lifespan of its components, it is essential to promptly replace damaged bottom roller.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported