Agricultural and Construction Equipment Undercarriage Parts

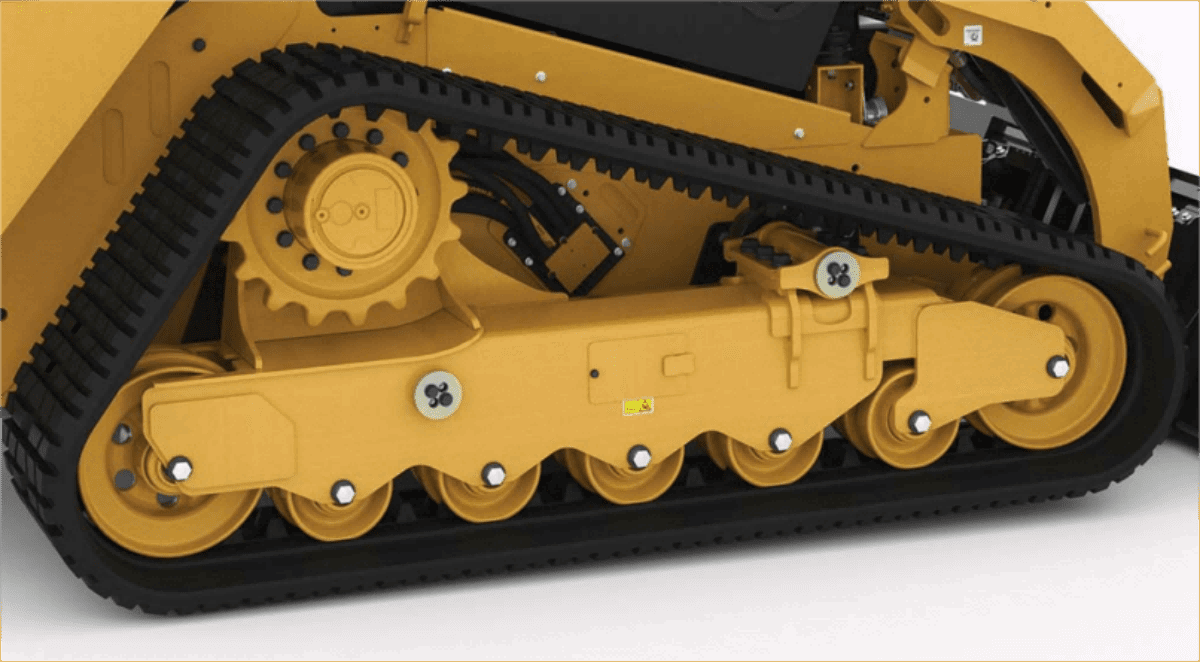

Compact Track Loader Rear Idler Fit for CAT279D 3041894

Crafted with precision and utmost durability, our Compact Track Loader Rear Idler, designed exclusively for CAT279D models, guarantees unrivaled performance on any terrain. Featuring superior materials and a robust construction, this idler is engineered to withstand the harshest conditions, providing exceptional wear resistance and longer service life. Trust our product's consistent excellence and rely on its unwavering quality for all your heavy-duty needs.

As a specialized manufacturer of compact track loader undercarriage parts, we understand the critical role that each component plays in the overall performance of your machinery. Our years of production experience, coupled with advanced manufacturing processes, ensure that every part we produce, including the Compact Track Loader Rear Idler Fit for CAT 279D 3041894, meets the highest standards of quality and durability.

Selecting the right rear idler for your CAT 279D is essential to maintaining the efficiency and longevity of your equipment. Our CAT279D Rear Idler is designed to provide exceptional performance in the most demanding environments, making it the ideal choice for customers who prioritize reliability and value.

At the heart of our product’s durability is our commitment to using only the highest quality materials. The rear idler is constructed from premium-grade steel and other robust materials that have been carefully selected for their resistance to wear, impact, and harsh operating conditions. This focus on material quality ensures that our idler can withstand the rigors of daily use, significantly extending the life of your machinery and reducing maintenance costs.

With years of manufacturing experience under our belt, we have honed our production processes to deliver parts that not only meet but exceed OEM specifications. Our manufacturing techniques are rooted in precision engineering, ensuring that each rear idler is crafted to exacting standards. This meticulous attention to detail results in a component that fits perfectly, operates smoothly, and enhances the overall performance of your CAT 279D.

We take quality control seriously, implementing rigorous testing and inspection protocols throughout the production process. From the selection of raw materials to the final product testing, every stage is monitored and evaluated to ensure that our rear idlers are free from defects and ready to perform reliably in the field. This commitment to quality gives you confidence in the durability and dependability of every part you purchase from us.

Our international customers demand more than just high-quality products; they require assurance that the components they invest in will deliver consistent performance and value. We recognize the unique challenges faced by our global clientele and strive to provide solutions that meet their specific needs, whether it's durability, precision, or after-sales support. Our rear idler for the CAT 279D is designed with these requirements in mind, ensuring that it meets the diverse needs of operators around the world.

Beyond the rear idler, our extensive range of undercarriage parts for compact track loaders, including other models of CAT and leading brands, underscores our capability as a full-service supplier. This wide selection allows you to source all the necessary parts from a single, reliable partner, ensuring consistency in quality and reducing the complexity of your supply chain.

We believe that our responsibility to our customers extends beyond the initial purchase. Our exceptional after-sales service is designed to provide ongoing support, whether you need technical advice, assistance with installation, or help resolving any issues that may arise. Our dedicated support team is always ready to ensure that you get the most out of your investment, making us a partner you can rely on for the long term.

Address : Building 17, Block 9, Section D, 27th Road, Chenghui International Hardware and Electrical City, Xiamei Town, Nan'an City, Quanzhou, Fujian Province

Wechat :

Please read on, stay posted, subscribe, and we welcome you to tell us what you think.

Copyright © 2024 Quanzhou Futeng Machinery Engineering Co.,Ltd All Rights Reserved.

Sitemap

|

Blog

|

Xml

|

Privacy Policy

Network Supported

Network Supported